Overview

Color

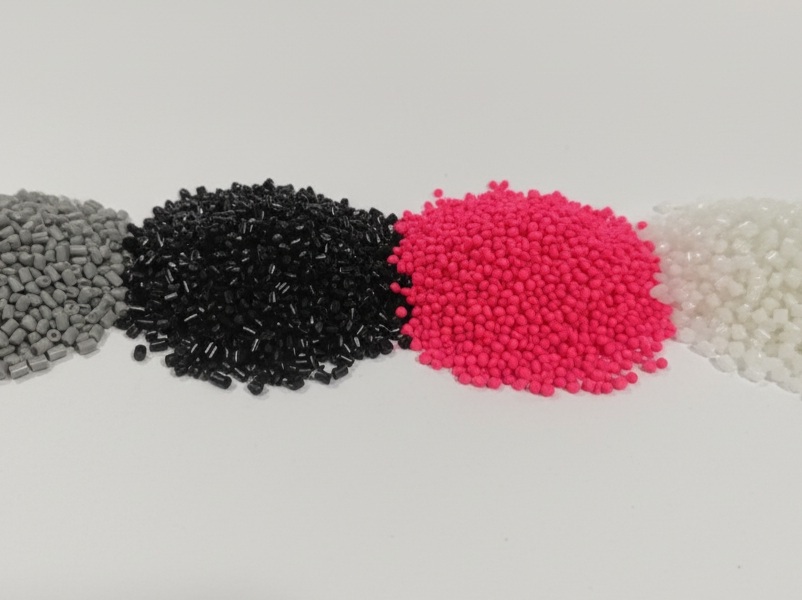

Masterbatches are highly concentrated mixtures of

organic and inorganic

pigments or dyes dispersed in a polymer carrier resin. They are used to

impart vibrant, consistent, and customized colors to plastics, while also

enhancing functional properties such as UV stability, heat resistance, and

processability. With advanced dispersion technology and shade-matching

expertise, color masterbatches deliver precise hues, brightness, and durability

across diverse applications.

Physical & Chemical Properties

- Pigment/Dye Content: Optimum selection of grade

depending on shade intensity and application.

- Carrier Resin: PE, PP, PS, PET, ABS or

universal carriers for compatibility with multiple polymers.

- Appearance: Free-flowing granules in

desired shades.

- Heat Stability: Engineered to withstand

processing temperatures up to 300 °C.

- Lightfastness &

Weatherability:

High resistance to fading in outdoor applications (UV-stabilized grades

available).

- Color Consistency: Controlled through CIE LAB

values for precise reproducibility.

Applications

- Packaging: Bottles, films, containers,

and caps with brand-specific colors.

- Consumer Goods: Toys, appliances,

houseware, and lifestyle products.

- Automotive &

Electronics:

Aesthetic parts requiring durable, stable color.

- Fibers & Textiles: Colored nonwovens, carpets,

and technical fabrics.

- Construction Materials: Pipes, sheets, and profiles

with weather-stable shades.

Processing Techniques

- Injection Molding – multi-colored consumer

and industrial products.

- Blow Molding – bottles, containers, and

hollow articles.

- Film Extrusion – flexible packaging and

decorative films.

- Sheet & Pipe Extrusion – colored construction and

industrial profiles.

- Fiber Spinning – textiles, carpets, and

nonwovens.

Sustainability

- Heavy-metal

free pigments for food-contact and eco-safe applications.

- Optimized

formulations reduce colorant usage while maintaining vibrancy.

- Recyclable

and reprocessable grades ensure compatibility with circular economy

systems.

- Available

in bio-based and recycled polymer carriers, supporting

sustainable plastic solutions.

- Long-lasting

color stability reduces need for frequent product replacement, minimizing

waste.